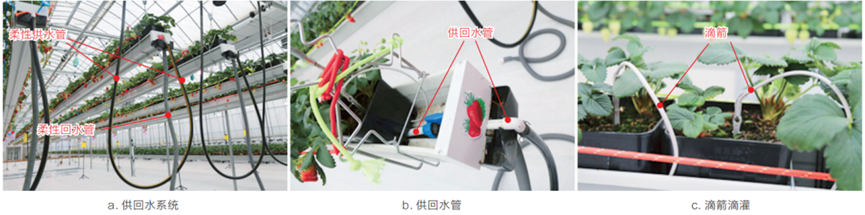

Strawberry planting water supply and return system

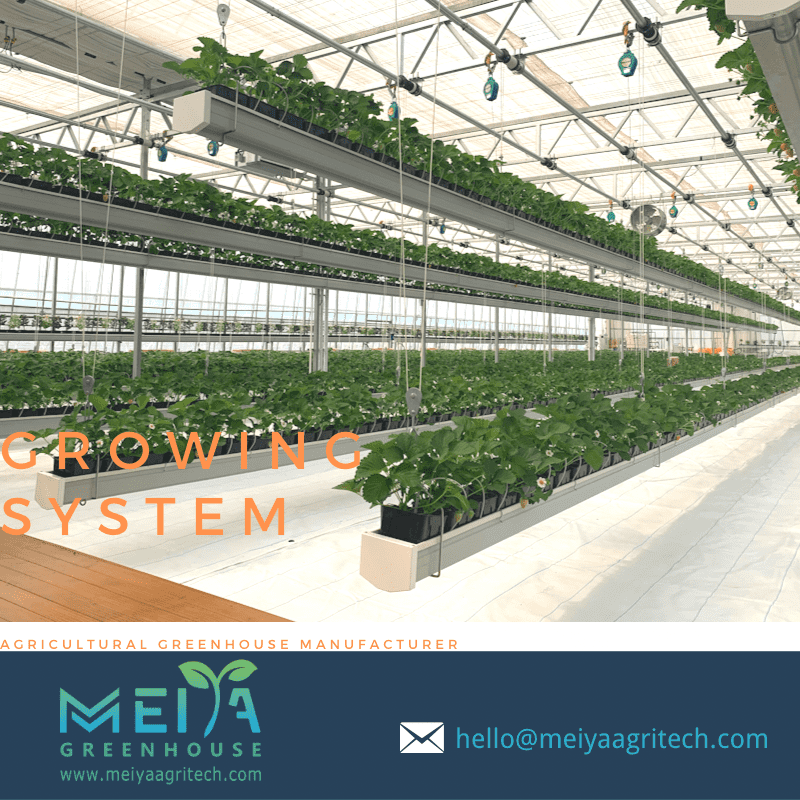

The water supply and return system for strawberry cultivation uses a centralized water supply and return system at one end of the cultivator. Since the cultivator is hung in a liftable way, two types of water supply and return pipes are used for the cultivator: one is a rigid pipe that is stationary, and the other is a flexible pipe that moves up and down with the cultivator.

During irrigation and fertilization, the supply liquid from the fresh water tank and the original liquid storage tank is sent to the water-fertilizer mixer according to the set water-fertilizer ratio, and then sent to the top of the cultivation hanger through the main water supply pipe (the main water supply pipe is installed on the greenhouse truss along the span of the greenhouse), and the flexible rubber hose leads the irrigation water from the main water supply pipe to the end of each cultivation hanger, and then connects to the water supply branch pipe set in the cultivation tank.

The water supply branch pipe in the cultivation tank is arranged along the length of the cultivation tank, and the drip arrow capillary pipe is connected along the way according to the arrangement of the cultivation bowl, and the nutrient solution is dripped into the cultivation substrate of the cultivation bowl through the drip arrow. The excess nutrient solution from the substrate is discharged into the cultivation tank through the drainage holes at the bottom of the cultivation tank and collected in the drainage ditch at the bottom of the cultivation tank in a uniform manner.

At the end of the cultivation tank, an opening is set up to connect the return liquid collection tank, and a return liquid pipe is connected under the collection tank to collect the collected return liquid and discharge it into the return liquid tank.

Return liquid utilization

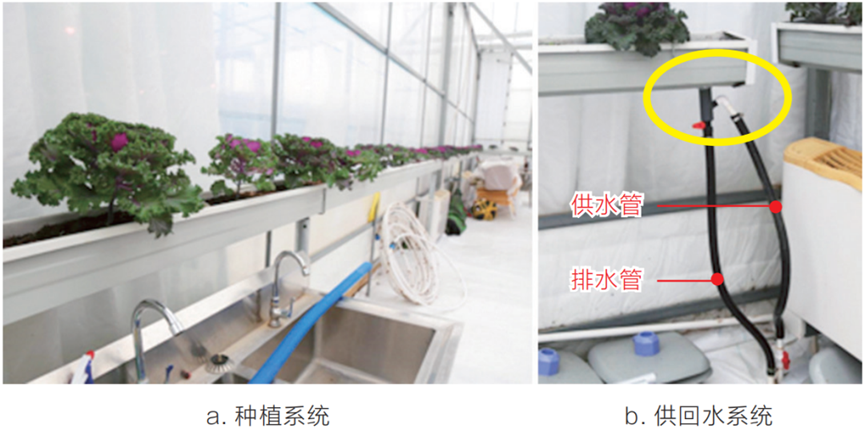

Instead of using the closed-loop cycle operation of the strawberry production system, this greenhouse irrigation return liquid is collected from the strawberry cultivation tank and used directly for the cultivation of ornamental vegetables.

The same fixed height cultivation tank as the strawberry cultivation is set at the side wall position around the greenhouse, and the cultivation tank is filled with cultivation substrate for growing ornamental vegetables. The irrigation nutrient solution is directly used for strawberry irrigation, and the fresh water in the storage tank is used for daily irrigation.

In addition, the supply and return piping design of the cultivation tank combines the supply and return ports of the cultivation tank into one, and the tidal irrigation mode is used in the cultivation tank, with the valve of the water supply pipe opened and the valve of the return pipe closed during the water supply period, and the valve of the water supply pipe closed and the valve of the drain pipe opened during the liquid discharge period.

This irrigation method eliminates the need for irrigation water supply branch pipes and capillary pipes in the cultivation tank, saving investment and having basically no effect on the production of ornamental vegetables.

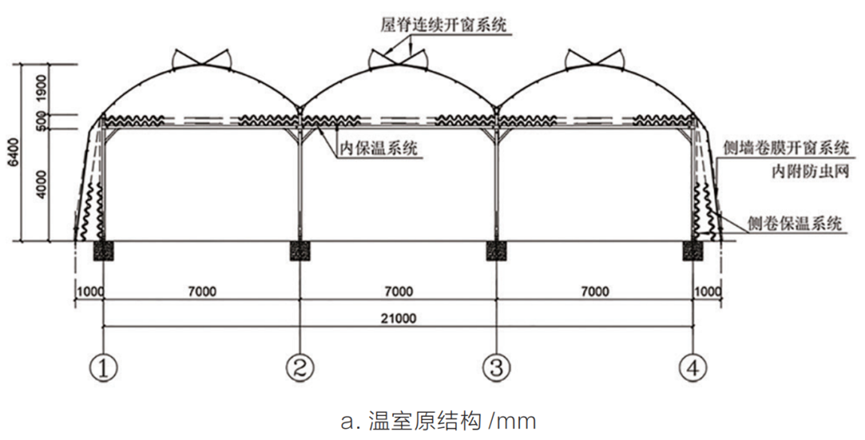

Greenhouse and supporting facilities

The greenhouse is 47 m long, 23 m wide, with a total area of 1081 m2. 7.0 m in span, 3.0 m in openings, 4.5 m in eave height and 6.4 m in ridge height, with 3 spans and 15 openings. In order to enhance the heat preservation of the greenhouse, a 1.0 m wide heat preservation corridor was set up around the greenhouse and a double-layer indoor heat preservation curtain was designed.

The greenhouse was designed with a double-layer internal insulation system for the roof and walls

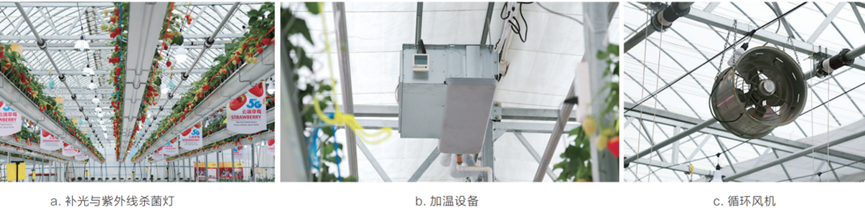

In order to ensure the light requirements for crop growth, a supplemental light system was added to the greenhouse renovation. The greenhouse supplemental light adopts bioeffect lamps, each lamp has 50 W power, 2 columns are arranged per span, the spacing of each column of lamps is 3 m, the total supplemental light power is 4.5 kW, equivalent to 4.61 W/m2 per unit area, and the supplemental light intensity can reach more than 2000 lx at 1 m high position.

Along with the installation of fill-in lamps, a column of UVB UV lamps was also installed in each span with a spacing of 2 m, which was mainly used for the occasional disinfection of the air in the warm room. The power of a single UVB lamp is 40 W, and the total installed power is 4.36 kW, equivalent to 4.47 W/m2 per unit area.

The greenhouse heating system uses a more environmentally friendly clean energy air-source heat pump, which sends hot air into the greenhouse through a heat exchanger. The total power of the air source heat pump in the greenhouse is 210 kW, and 38 heat exchange fans are evenly dispersed in the room, with each fan dissipating 5.5 kW of heat, which can ensure the air temperature inside the greenhouse is above 5°C on the coldest day when the outdoor temperature is -15°C, thus ensuring the safe production of strawberries in the greenhouse.

In order to ensure the uniformity of air temperature and humidity in the greenhouse and to create a certain air movement in the room, the greenhouse is equipped with a horizontal air circulation fan. The circulating fans are arranged in the greenhouse span with a distance of 18 m and a single fan power of 0.12 kw.

Welcome to leave your comments and discuss with us your thoughts!