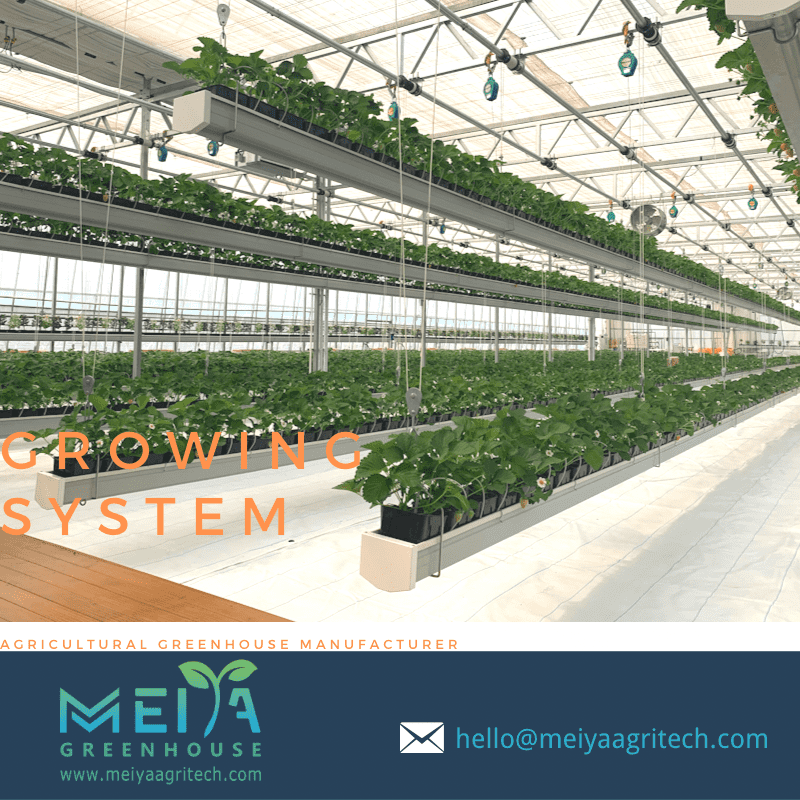

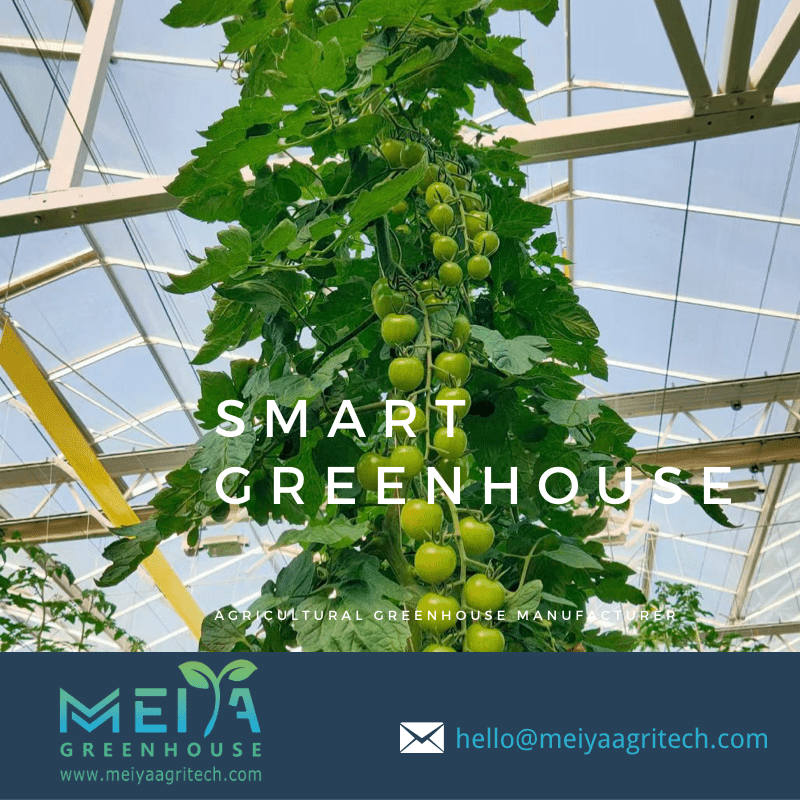

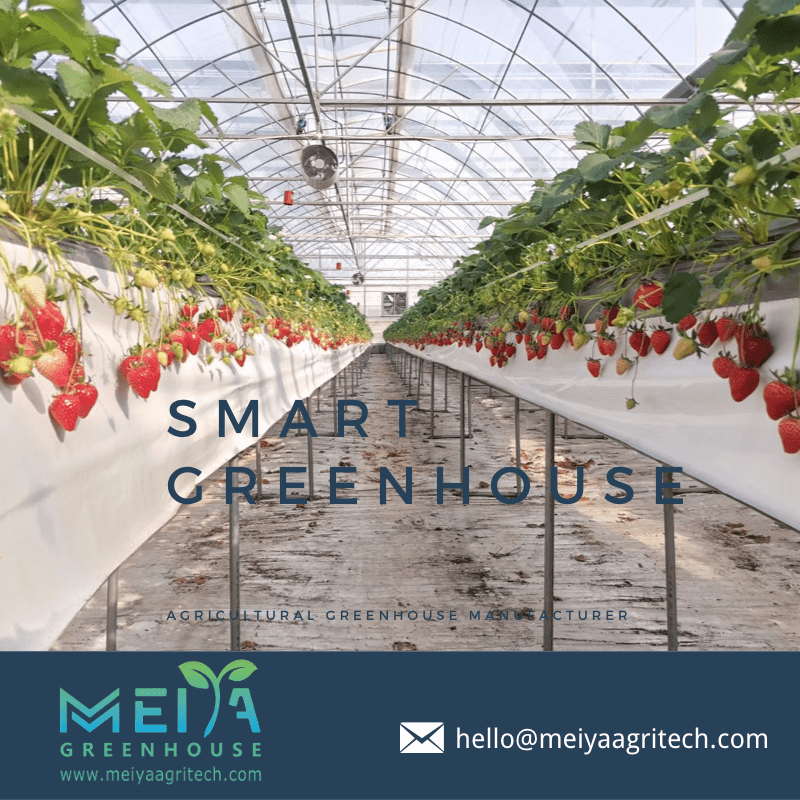

This is a strawberry cultivation greenhouse that integrates technology display, sightseeing, picking and recreation, and is equipped with a liftable strawberry frame and hanging system.

Cultivation tank and cultivation method

The water supply and drainage is concentrated in the bottom of the cultivation tank, and a rib is raised in the long direction in the middle of the bottom of the cultivation tank (from the inside of the cultivation tank, a bottom groove is formed at the bottom), and the water supply pipe is laid directly in the bottom groove, and the water drained from the cultivation substrate is collected in this groove and discharged from the end of the cultivation tank.

The advantage of using a cultivation bowl is that the bottom of the bowl is set up away from the bottom of the cultivation tank, so that the substrate does not form a high water layer in the lower part of the substrate and the overall aeration of the substrate becomes better; secondly, the disease between plants does not spread with the flow of irrigation water; thirdly, the substrate does not leak in the cultivation bowl and the overall look of the cultivation frame is neat and beautiful. The disadvantage of this practice is that drip arrow irrigation and cultivation bowl planting increase the investment in equipment construction.

Cultivator hanging and lifting system

The hanging and lifting system of the cultivator is generally the same as that of the traditional strawberry lifting cultivator. The cultivation trough hanger is looped around the cultivation trough, and the hanger is connected to the reversing wheel by the adjustable length flower basket screw (used to adjust the consistency of the installation height of the cultivation trough), and the reversing wheel is wound with the lifting rope, one end of which is fixed to the lower chord of the greenhouse truss, and the other end is wound on the winding wheel connected to the driving shaft of the motor reducer.

On the basis of the overall universal hanger system, some personalized accessories and facilities are also innovatively designed here to accommodate the special cross-sectional shape of cultivation tanks and the needs of sightseeing displays.

- Cultivator hanger buckle. The cultivator hanger is first of all a closed-loop buckle, formed by a steel wire bending and welding, with the same cross-section of all parts of the hanger and the same mechanical properties; secondly, in order to adapt to the shape of the bottom of the cultivator raised outward, the cultivator hanger also adopts a corresponding semicircular bend in the bottom section of the hanging cultivator; thirdly, the top middle of the hanger is bent into an acute angle bend, and the upper hook is directly hooked on the bend point, which not only ensures the cultivator’s This not only ensures that the center of gravity of the cultivation trough is stable and will not be deformed sideways, but also ensures that the hook is reliable and will not slip and misplace.

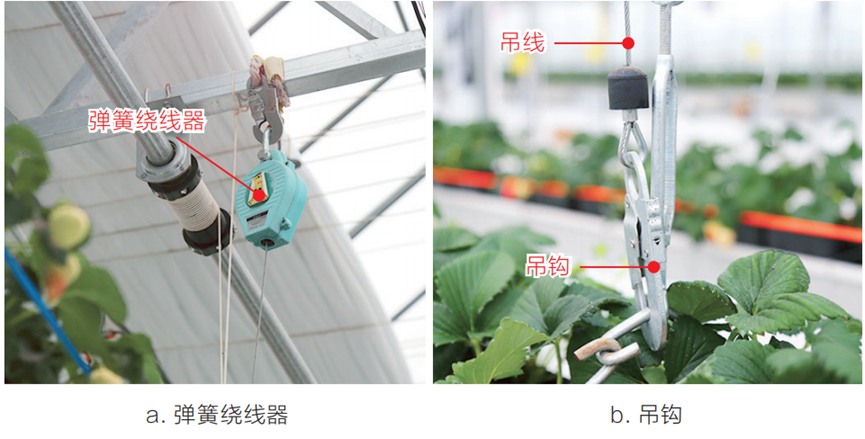

Safety hanging rope. On the basis of the traditional hanging system, a set of safety hanging system is additionally set up every 6 m along the length of cultivation tank. The requirements for the additional safety hanging system are, firstly, to run synchronously with the driving hanging system; secondly, to have sufficient bearing capacity. In order to achieve the above functional requirements, the design selected a set of spring winder hanging system to put away the cultivation tank hanging line. The spring winder is arranged in parallel with the drive hanger lift rope and hung on the lower chord of the greenhouse truss, from which the end of the hanger line is connected to the hook, which is hooked on the cultivation trough hanger.

Cultivation frame auxiliary production equipment

a. Plant combing system. The plant combing system here is mainly composed of two parts: plant combing bracket and colored silver light rope, in which the plant combing bracket is a partially bent overall U-shaped bending card and a U-shaped card double-branch limit bar. Both the U-shaped bend and the double-branch limit bar are made of galvanized steel wire.

The fruit and leaf separation rope is used to gather the strawberry branches and leaves within the width of the cultivation tank, while the strawberry fruits hang outside the cultivation tank, which is not only convenient for fruit picking, but also easy to protect the strawberry fruits from the direct spraying of the chemical solution during the plant protection operation, and can enhance the ornamental appearance of strawberry planting.

b. Mobile yellow board stand. Specially designed a movable yellow board frame, that is, a hanging yellow and blue board stand welded on a tripod, can be placed directly on the ground in the greenhouse and can be moved at any time.

c. Self-driving plant protection vehicle. The operation vehicle can carry the plant protection spraying machine, that is, the formation of self-driving spraying vehicle, according to the computer planning path in the indoor conditions without operators to carry out plant protection operations, can well protect the health of greenhouse operators.

Nutrient solution supply and irrigation system

The nutrient solution supply and irrigation system for greenhouse production in this project is divided into 3 parts: first, the clear water preparation part; second, the strawberry irrigation and fertilization system; and third, the reuse system of return liquid for strawberry cultivation. Here, the equipment for clear water preparation and nutrient solution configuration is collectively called the irrigation first part, and the equipment for supplying back water to crops is called irrigation equipment.

Prime System

Clear water preparation equipment should generally be configured with gravel filters to remove sand and water softening equipment to remove salt. After filtration and softening of clear water stored in the reservoir for backup.

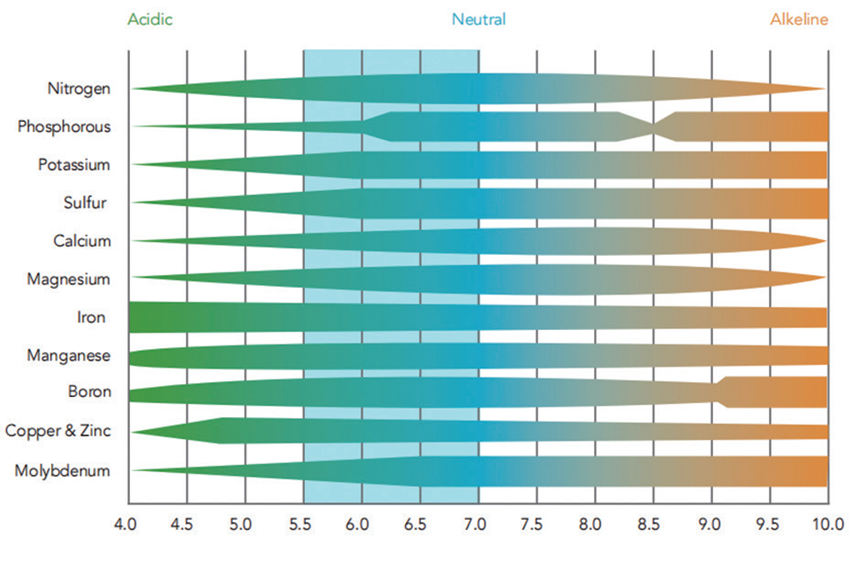

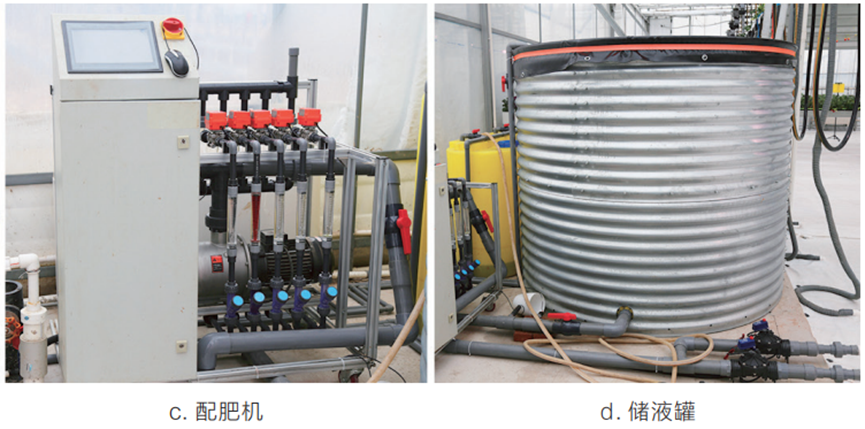

Nutrient solution configuration equipment generally includes A, B two kinds of fertilizer original liquid tank and acid tank for pH adjustment 3 kinds of raw material tanks and 1 set of fertilizer dispenser. During operation, the raw liquid in the A, B and acid tanks are mixed in proportion to the set formula through the fertilizer dispensing machine to form the nutrient solution, and the nutrient solution configured through the fertilizer dispensing machine is stored in the original liquid storage tank for use.

More information will be shared in the next post…