E. External sun-shading system

Transmission machinery: rack and pinion transmission.

Press the control box start switch button, and the motor starts. The motor drives the drive shaft through the transmission mechanism, the drive shaft drives the drive rod to move parallel to the curtain wire through the connection, and the drive rod pulls one end of the curtain to unfold slowly, all unfolded after touching the travel limiter switch, the motor stops, the trip operation ends.

The control box is equipped with manual control, if you need to stop in the middle, you can press the stop button to stop the operation.

F. Inner shade insulation system

System principle: In summer, the use of insulation shade screen to block the sunlight, to prevent excess solar radiation energy into the greenhouse, not only to ensure that crops can grow normally, but also to reduce the indoor energy gathering, thus reducing the temperature in the greenhouse, protecting crops from strong light burns, and make the indoor temperature drop 3-5 ℃;

In winter, the insulation shade screen has the role of reflecting the indoor infrared, preventing its role of external escape, to reduce heat loss, so as to improve the indoor temperature, reduce energy consumption and reduce winter operating costs.

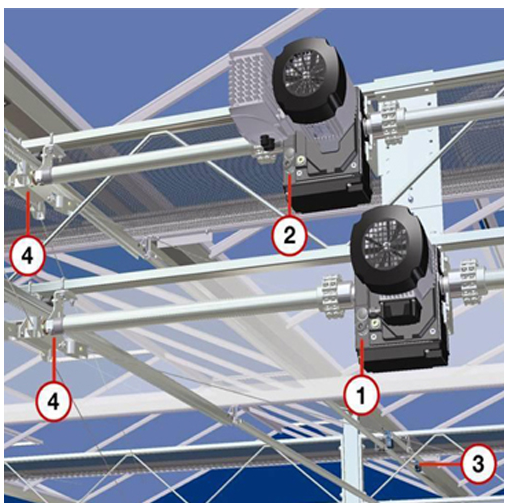

G. Wet Curtain Cooling System

Principle: Wet curtain/fan cooling system uses the evaporative cooling principle of water to achieve the purpose of cooling. The core of the cooling system is to ensure that the water is evenly drenched throughout the wet curtain wall. When the air passes through the wet curtain medium, the water-air exchange with the surface of the wet curtain medium reduces the temperature of the air. It is one of the most economical and effective cooling methods.

H. Naural ventilation system

The top of the greenhouse is equipped with a rack and pinion electric window ventilator, which can open the window at the top and make the air inside and outside the greenhouse form convection to achieve the effect of dehumidification and cooling. This system is easy to maintain, economical and practical and has reached the advanced international level.

I. Heating system (heat source is self-provided)

Water heating: round wing type hot-dip galvanized radiator

Adopting water heating, with hot water as the heat source, the room temperature drops slowly and the heat dissipation is even, which will not produce local drastic effects on the crops. The pipes, connections and valves are made of rust-proof and anti-corrosion materials.

Round-wing hot-dip galvanized radiators are arranged according to the growing needs of crops and temperature gradients, hot-dip galvanized round-wing radiator pieces, hot water in and out of the heat pipe temperature of 95C ~ 70C, respectively, according to the actual planting needs. The round-winged hot-dip galvanized radiator used has a large heat dissipation area, and the temperature is raised higher and cooled down more slowly, so the heat dissipation is very even, so it will not affect indoor crop growth. And it is anti-corrosion and anti-rust, good quality, and long life.

J. Intelligent control system

(1) System objects

Suitable for production or ornamental and scientific research type continuous greenhouse (single layer film, double layer inflatable film, PC board, glass greenhouse).

(2) System function

a. Control of external shading system.

b. Control of the internal shading system.

c. Control of wet curtain fan system.

d. Control of wet curtain outward turning window

e. Control of the natural ventilation mechanism.

f. Control of the lighting system.