Formulation adjustment

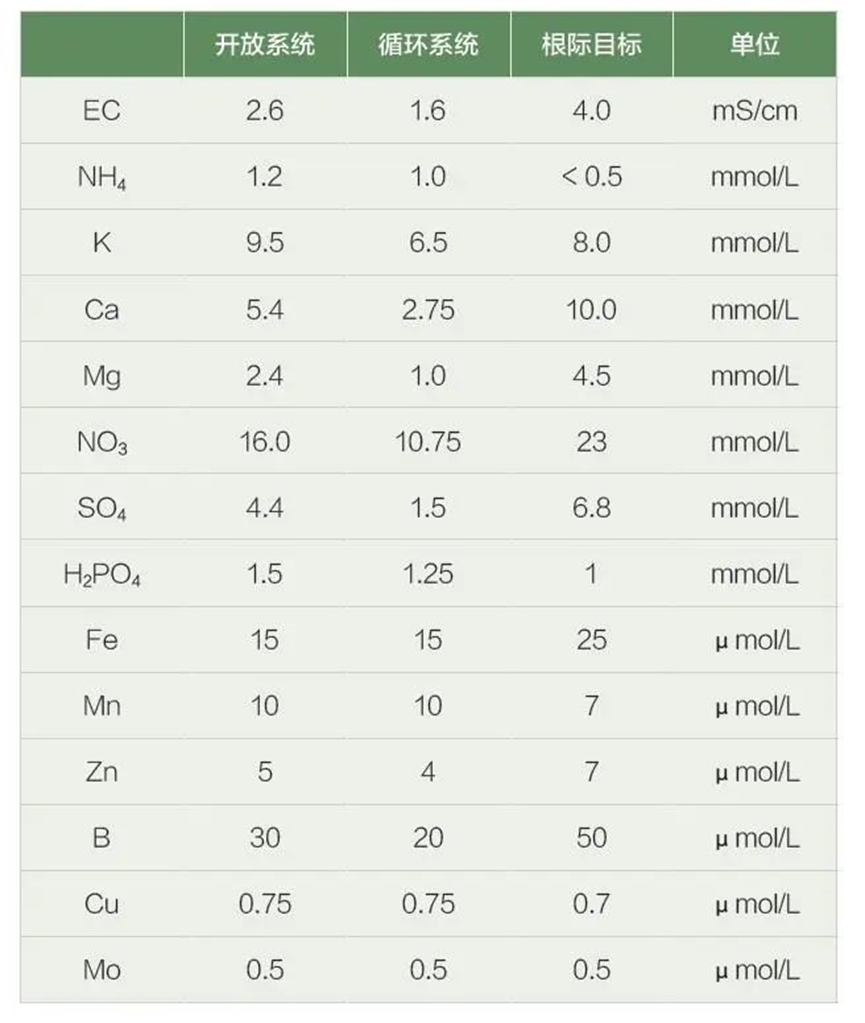

The initial source of the formulations was based on the composition of the crop from the content of each element of the plant after the plant ash test. Table 2 shows the initial formulations for tomatoes, representing the open system (no return fluid recycling), the nutrient recycling system, and the inter-root concentration of each ion.

Formulation adjustments are made at the base formulation level based on the results of regular nutrient solution/leaf tissue testing.

Liquid return management

The return liquid is the excess nutrient liquid that flows out of the substrate bag during irrigation. The return liquid volume is calculated as the ratio of the return liquid volume of individual substrate strips to the total irrigation volume. In the Netherlands, due to strict environmental protection laws, growers are restricted from discharging return liquid into the surrounding area, so in modern Dutch greenhouses, return liquid needs to be recycled through a collection system, UV disinfector and then reused. Currently, irrigation systems are divided into open systems, where the return liquid is discharged directly, and recirculation systems, where the nutrient solution is recycled and disinfected for reuse.

The purpose of the return solution is to ensure sufficient water and fertilizer supply to the plants and to maintain the inter-root EC and ion concentration in the right range, as shown in Table 2. In general, for each day’s return solution, it mainly comes from the second stage, the first stage should not exceed 40% of the total return solution for that day, and the third stage should not be returned. The amount of return solution depends on the amount of radiation accumulation in a single day. Usually, the root system absorbs more water than fertilizer under high radiation conditions on sunny days, so the amount of return solution should be increased on sunny days to ensure that the inter-root EC is stable and within a reasonable range.

After disinfection, the return solution is stored in the return solution disinfection tank. In the case of recycling the return solution, regular (2~4 times per month) nutrient solution composition testing is required to adjust the mother liquor formula according to the return solution. For example, if the target concentration of element B in the feed solution is 50 nmol and the concentration of the ion in the return solution is 60 nmol, the concentration of element B from the mother solution should not be less than 25 nmol to ensure the concentration of the ion in the feed solution under the changing composition of the return solution and to avoid plant deficiency.

Nutrient solution management

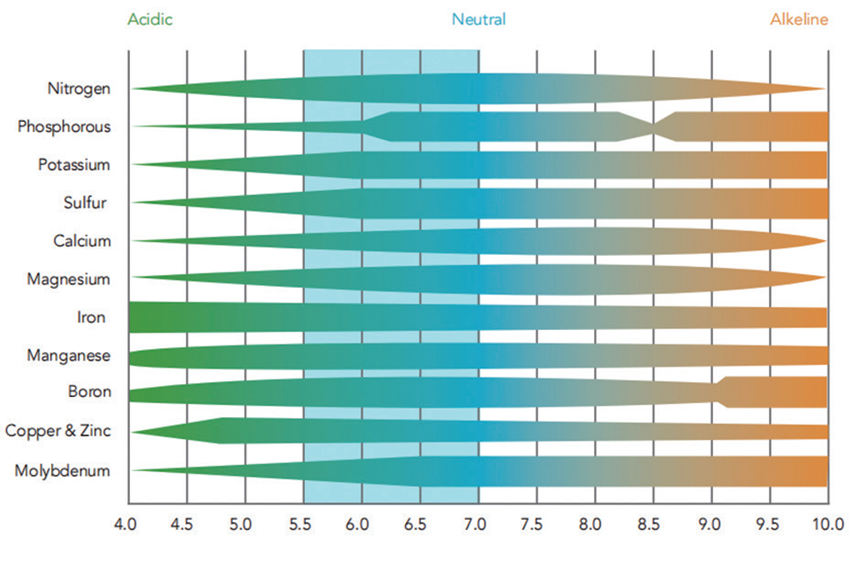

The management of nutrient solution mainly includes nutrient/return solution EC, pH, temperature detection and control, EC reflects the concentration of large amount of elemental anions and cations in the nutrient solution, the higher the value represents the higher the sum of ion concentration in the nutrient solution, the appropriate EC for tomatoes in different growth stages varies, the tomato plant’s water demand is higher than the nutrient ions in summer, so the inlet EC and inter-root EC are low in summer, generally It is recommended that the inter-root EC should be 3-5 mS/cm and the inlet EC should be 2.5-3.5 mS/cm. In winter, when radiation intensity is low and humidity is high, plants tend to favor nutrient growth, so a slightly higher inlet EC and inter-root EC is maintained, with an inter-root EC of 4-6 mS/cm and an inlet EC of 3.5-4.0 mS/cm. The pH of nutrient solution and inter-root pH are 5.5~6.5, which is weakly acidic. The main consideration is the effectiveness of inter-root ions that can be absorbed by plants.

Inter-root pH can be adjusted in two ways, one by adjusting the pH of the feed solution with nitric acid, phosphoric acid or potassium hydroxide, and by irrigating the substrate heavily to restore the substrate pH to normal values. The other is by physiological alkaline salts (nitrates) or physiological acid salts (ammonium salts), where the root system releases H+ when absorbing NH4+ ions, resulting in a decrease in inter-root pH, and releases OH- ions when absorbing NO3- ions, resulting in an increase in inter-root pH.

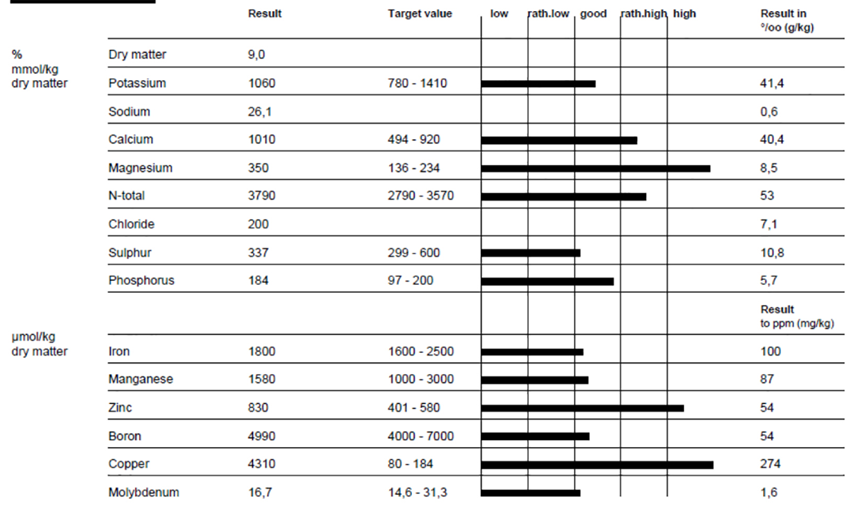

During tomato production, the EC and pH of the irrigation and return solutions need to be monitored daily, usually 30 min after the end of the last irrigation of the day. In addition, for the adjustment of the formula, it is recommended that the incoming and returning liquids be tested once a week to ensure the accuracy of the formula based on the test values, and that the formula be adjusted in real time based on the test results, and that the nutrient solution be tested every week, and in case of deficiency, the leaves be tested at the same time, as shown in Figure 5. If the temperature is too low, the enzyme activity in the roots and cells will be reduced, which will affect the absorption of water and fertilizer.

Summary

Tomato water and fertilizer management in production is a dynamic and balanced process. With the help of modern water and fertilizer management equipment, and based on the laws of tomato growth, growers adjust the nutritional formula to provide accurate water and fertilizer supply for tomato growth and achieve yield quality optimization. In the future, intelligent water and fertilizer control can be further strengthened to achieve high quality and high yield of tomatoes.