The upside the semi-closed technology delivers is significantly amplified in parts of the world where harsh prevailing environmental conditions such as extreme heat, humidity, cold, or a combination of all depending on the season.

Beyond the climatic advantages the technology further creates value through its ability to:

· integrate with supplemental lighting, providing cooling when blackout curtains are used

· significantly reduces the required number of screened roof vents which defuse light, reducing yield

· utilize low-grade heat sources and waste energy through carbon capture integration

Along with many other applications for crops that are known to be particularly sensitive to climatic conditions and changes.

Addressing Extreme Heat:

In areas where extreme heat occurs, particularly when combined with low humidity, these semi-closed greenhouses can be very effective in creating a growing climate that can be very beneficial for plant growth. These areas occur in many parts of the world where conditions were deemed too harsh to grow prior to the advent of semi-closed technology. These developments have also greatly increased productivity in existing production areas by giving the grower much more control of climate. Often temperatures inside with a healthy crop can be 10C cooler inside than outside.

Addressing Extreme cold:

In climates of extreme cold the semi closed greenhouse can also have many advantages particularly when supplemental light is used. The system can ventilate when it is cold outside but warmed inside by lights and or the sun. This can be particularly effective for keeping the humidity under control and air exchanges happening to maintain proper crop climates.

Conditions when blackout screens are closed:

When screens are used for crops that required short day treatment, blackout curtains are commonly used. In a passively cooled greenhouses, the temperature often gets too hot and/or humid for many crops. The semi closed design allows continual cooling and climate control even when the screens are closed. This is also possible when you wish to use screens for defusing light or reducing sun intensity. Most screens are porous enough to allow the screens to be closed 100%.

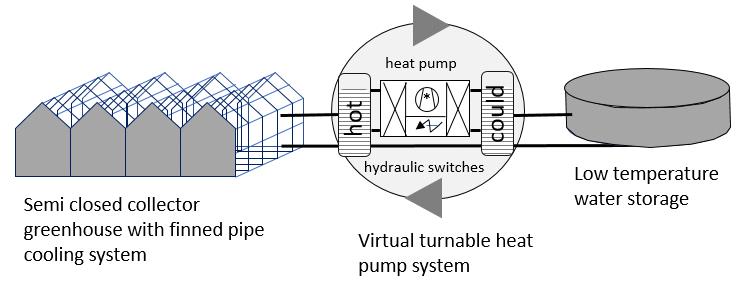

Low grade heat:

When one wishes to use low grade heat that is often referred to as waste heat as the temperatures are generally too low for commercial use. Most semi closed greenhouses can utilize this heat very effectively even in extremely cold climates. The sources of this heat are often found as the waste flue gas byproduct from power plants or manufacturing facilities.

Widely fluctuating conditions:

Areas that have severe temperature fluctuations and or wind shifts the semi closed greenhouses delivers the tools that enable a grower to react quickly and maintain uniform indoor conditions, which are critical to plant health and quality.

Sensitive crops:

Semi closed systems, have much greater control in air movement and humidity control reducing potential diseases such as botritus and other fungal issues that can occur in many growing regions.

Further advantages that reduced costs and/or enhance conditions include:

· As there is much more controlled air exchanges, CO2 can be used more sparingly to maintain lower levels or raised easily to higher levels

· Pressurized greenhouse environment is much easier to control pests as air is always blowing out when doors are opened to outside or other non-pressurized areas

· The climate is more homogeneous due to less outside influences such as wind and the ability to exchange air under rainy conditions due to not requiring open vents during rain and windy periods

· As the greenhouse can operate with only 4% of the vents required in traditional greenhouses light transmission can be enhanced by as much as 15% in locations requiring insect screens.

When you are contemplating or choosing to build a semi closed greenhouse it is important to ensure the following conditions are met:

1. Performance is based on the quality and experience of the site engineering, the component manufacturing and their ability to deliver a greenhouse can be leveraged to realize the potential of semi closed greenhouse technology.

2. Row or tube lengths should not exceed 125 meters and should utilize properly configured double tubes. Without the double tube and a specific vent hole configuration your climate will be compromised particularly at higher fan speeds.

3. Be aware in crops where bees are used, protect your fans and radiators with bee screens as the pollinators can shorten the life of the fans and plug radiators.

4. Integrate a climate control computer that is designed specifically for controlling your greenhouse. Many conventional systems are not calibrated correctly or do not have the features required to maximize your control.

5. Your grower needs to be open to learning and understanding the design, its capabilities and where you need to change your thinking to get the maximum results.

6. Keep your greenhouse pressurized at all times to maintain a more homogeneous climate, maintaining pressures between 10 and 20 pascal.

7. If your crop system uses tables, they need to be designed so air can flow through them. If this is not done, you will not have good growing conditions in the center of your tables.

8. Most semi closed greenhouses have patents on the components and or designs. Make sure that your supplier holds patent rights or you and your supplier maybe liable for patent infringement with significant cost implications.

Semi closed greenhouses are very effective when designed properly and used with the right growing knowledge. The most common mistake is not changing your growing style to match the tools of your greenhouse system.